A Large Diameter Turning Centre Added to Complement Our Machining Capabilities

After a lot of painstaking research we chose the CMZ over the competition believing its high 75Nm driven tooling torque and 77mm diameter barfeeding capacity will bring a whole range of machining opportunites to our present and future workload..

Christopher Harley - Managing Director

Integrated Spindles. Higher precision, surface finish and roundness

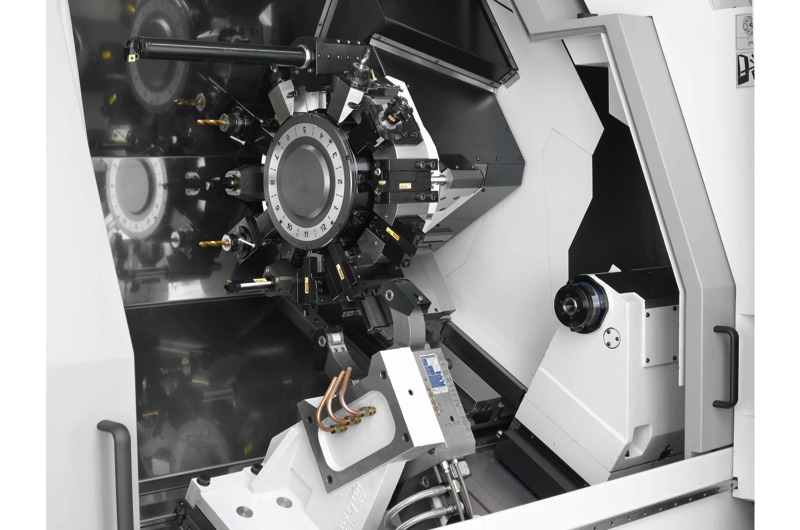

The TC30YS CNC Lathe employs two integrated spindle motors to increase accuracy and reduce machining times. The spindle is driven through a motor integrated into the headstock body itself giving outstanding spindle robustness and vibration dampening that significantly improves surface finish and roundness.

Spindle acceleration times are shortened by about 20-50% because of the reduced inertia and higher loading capacity of the oil-cooled headstocks

Spindle Power to spare

The TC30YS offers a huge 42KW of main spindle power going Brimor Engineering enough power to machine even the toughest of materials

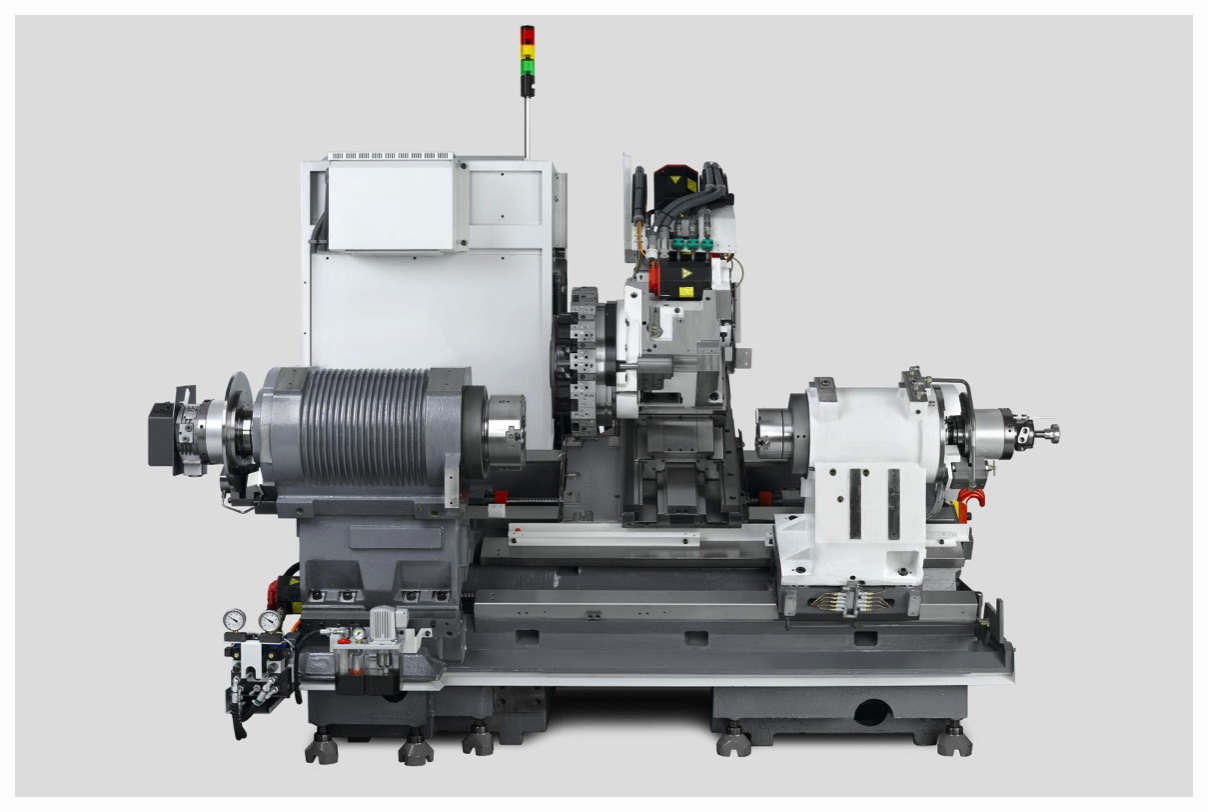

CMZ TC30YS

The CMZ TC30YS gives Brimor Engineering a large bar diameter turning capacity of up to 76mm through the spindle. A powerful class-leading driven tooling capability delivered on a solid box slideway ensuring maximum rigidity and unparalleled accuracy.

Coupled with the latest Hydrafeed barfeed, turning and machining runs continuously throughout the day.

Coupled with the latest Hydrafeed barfeed, turning and machining runs continuously throughout the day.

Our latest arrival is reducing lead times and extending our capability

Machine specifications

| Max Swing | 580 mm |

| Max turn dia | 520 mm |

| Max turn length | 773mm |

| Spindle kW | 42kW |

| Bar dia | 77 mm |

| Chuck Size | 10 " |

| Control | Fanuc 31i |

| Spindle rpm | 3,500 |

| Turret | 16 |

| Driven tooling | 16/4,000 kW/rpm |

| Sub rpm/kw | 5,000/14 |

| Sub Spindle | C axis |

| Y axis mm | 140 (+80mm/-60mm) |

The latest Fanuc 31i Control

High-speed, high accuracy machining is achieved utilising not only a CNC that controls the machine with nanometer (0.000001mm) resolution but also servo and drives that accurately position the machine.

Ethernet connectivity allows Brimor Engineering to work 'offline' programming the next job while one is running and downloading it by FTP ready for the next production run

Servo turret with hydraulic coupling

The TC30YS incorporates a large diameter turret disk which reduces the interferences between tool and chuck. A large 230mm diameter curvic coupling produces maximum clamping power to the turret ensuring rigidity in turning and milling is maintained throughout the lathe. Indexing time is a fast 0.2 seconds between adjacent turret positions and 0.5 seconds for a 180 degree rotation.